Used Hay Equipment in 2017: What You Need to Know

February 2017

As we enter a new year, it is a natural time to assess machinery needs and shop around a little. To help the search, we reached out to a couple of experts to discuss used equipment market tips and trends for 2017.

Meet the Experts

Greg Peterson, or as he is more widely known “Machinery Pete,” has been an expert in all things machinery since 1989 when he first began researching and tracking auction prices. Over the years, his expertise made his website (MachineryPete.com) one of the most trusted resources in the industry for market analysis and used farm equipment listings.

Dave Mowitz has been a content creator in the agriculture industry for more than 30 years. He currently manages content for Successful Farming magazine, serves as an editor of the Ageless Iron Almanac and hosts The Machinery Show on RFD-TV.

How does the hay and forage market look for 2017?

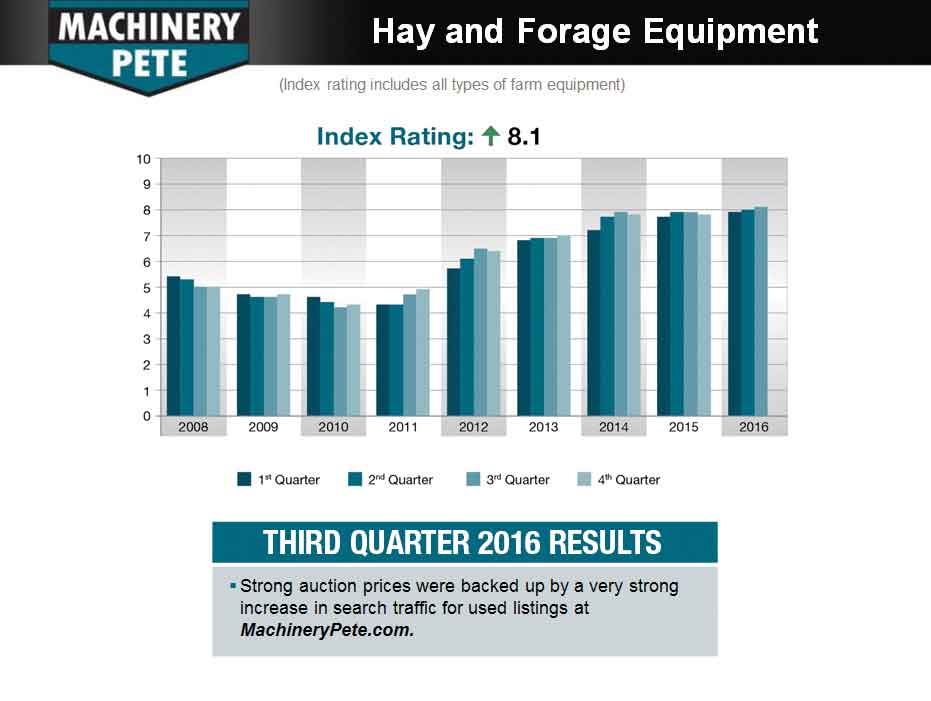

Peterson: “On MachineryPete.com there are 100,000 pieces (of equipment) that dealers have for sale. We track the traffic every day, so by isolating (the data) to the hay and forage category, I can tell you that in the third quarter of 2016 the traffic for mower conditioners was up 152.3 percent, tedders up 137.3 percent and round balers were up 44.5 percent. So, this gets interesting when you compare the search traffic patterns to the actual auction price data patterns. This tells us that people are not only looking, but they are thinking of buying.”

Mowitz: “I have noticed that the auction and dealer values of late-model (1-3 years old) large round balers, self-propelled windrowers, mower conditioners, disc mowers and rakes have softened. Overall, you can buy any of these items for 10-20percent less than a year ago unfortunately thanks to the depressed cattle prices. This situation creates a golden opportunity fora farmer or rancher to buy a late-model, little-used round balers, tedders and rakes for significant savings.”

How has the internet changed used equipment sales?

Peterson: “Geography is always interesting to track when buying or selling used equipment, that’s for sure. How are prices in northeast Iowa compared to southern Ohio, or if you’re based in western Wyoming? Is it raining there? It can get competitive if you’re selling into a (high demand) area.

Mowitz: “The Internet has leveled the playing field when it comes to pricing used equipment. As such, a 2- or 3-yearoldlarge round baler in Nebraska in great condition will be priced about the same as a similar baler in Pennsylvania. That being said, geographic pricing opportunities do present themselves on occasion.”

What are the most sought after equipment pieces right now?

Peterson: “One trend that we’ve seen is that the smaller capacity equipment doesn’t depreciate as much. Everything in ag is getting bigger and bigger which is great, but what’s happened is so many companies have quit making (smaller equipment). Now when we see a nice 15- to 20-year-old (small capacity item), there’s 10 guys fighting over it. So generally speaking, those smaller horsepower tractors and round balers, they are really holding their value.”

Mowitz: “A large round baler that is well equipped – with options like a crop-cutter or silage-special gear, for example – and has had little use (low bale production) is always a hot ticket item whether it’s up for sale at an auction or is in the front-line on a dealer’s lot. And, thanks to the Internet and the ability to search such sites as

FastLine.com, AuctionTime.com andMachineFinder.com, a farmer or rancher can shop the nation for available equipment.”

Is there a perfect age for used equipment?

Peterson: “When it comes to the age of equipment, if something is 10 years old it really starts to hold its value. Whether it’s a grinder mixer, a round baler, a rake, etc.— if it’s nice and there’s some age on it, there is going to be some demand for it. That would apply across the entire forage category.”

Mowitz: “The sweet spot is a piece of equipment that has had little use for its age. This rule applies to any type of equipment or any age. A good example of this would be a 10-year-old tractor that has less than 1,500hours of use and has been well cared for — and this equipment exists. For example, I recently uncovered42 examples of 2014 Class 8 combines that had less than 400 separator hours. Shoot, those combines were hardly broken in and yet they were selling at 3-year-old combine prices.”

What’s the most important piece of advice you have for buyers?

Peterson: “The first step is to contact your local dealer. I come from a dealer family, the service they provide to you is great. Even if your local dealer doesn’t have what you need — these days, through their networks they can find whatever you need.”

Mowitz: “Always, always, always inspect the equipment before purchasing it at auction. If, for example, you are interested in a baler or mower conditioner that is up for sale at an auction, get to that sale hours in advance and take the time to thoroughly inspect the equipment to determine its condition. Also, find the auctioneer and ask them for the contact information of the person consigning that equipment for sale and then call that owner and ask how they cared for the equipment. I have found auctioneers to be some of the most honest folks in agriculture and sellers often follow suit.”

Best Practices for Buying Used Equipment

Yes, you can save a lot of money by buying used machinery, but there are a lot more benefits with used equipment than just saving a few bucks. Used equipment can be more reliable than newer machines and can experience fewer glitches —anything that may have occurred has probably already been found, tested and fixed. Plus, having a lot of money tied up in equipment can be very daunting in times of uncertainty. If you’re not confident in the market and need to add to your fleet, a used equipment purchase can be the better option.

USED Equipment Purchase CHECKLIST:

- See it in action. View equipment while it’s running before purchasing it and test it if you can. If you can’t, ask if they have any videos of it running.

- Check tire quality. If damaged this could help price negotiations.

- Ask for the serial number. This can help you do homework on the machine’s history.

- Check for the original manuals and prints.

- Look for cleanliness. If the machine doesn’t look well-kept it might not have been maintained mechanically very well either.

- Review the warranty program. Look for a solid used warranty program that ensures you will receive timely assistance if issues should arise when you get it home.

Tips

- Shop locally when you can. If you buy something far from home, be sure to factor in the cost it will take to get it back to your area before making the purchase.

- Understand the support offered. If something goes wrong, you need to be aware of the type of support the seller is offering.

- Find a trustworthy seller. Request references if you’re unsure about their credibility — if the seller doesn’t supply the information, move on.

- Be wary of fresh paint — this could indicate prior damage.

Best Practices for Buying Used Equipment

Yes, you can save a lot of money by buying used machinery, but there are a lot more benefits with used equipment than just saving a few bucks. Used equipment can be more reliable than newer machines and can experience fewer glitches — anything that may have occurred has probably already been found, tested and fixed. Plus, having a lot of money tied up in equipment can be very daunting in times of uncertainty. If you’re not confident in the market and need to add to your fleet, a used equipment purchase can be the better option.

USED Equipment Purchase CHECKLIST:

- See it in action. View equipment while it’s running before purchasing it and test it if you can. If you can’t, ask if they have any videos of it running.

- Check tire quality. If damaged this could help price negotiations.

- Ask for the serial number. This can help you do homework on the machine’s history.

- Check for the original manuals and prints.

- Look for cleanliness. If the machine doesn’t look well-kept it might not have been maintained mechanically very well either.

- Review the warranty program. Look for a solid used warranty program that ensures you will receive timely assistance if issues should arise when you get it home.

Tips

- Shop locally when you can. If you buy something far from home, be sure to factor in the cost it will take to get it back to your area before making the purchase.

- Understand the support offered. If something goes wrong, you need to be aware of the type of support the seller is offering.

- Find a trustworthy seller. Request references if you’re unsure about their credibility — if the seller doesn’t supply the information, move on.

- Be wary of fresh paint — this could indicate prior damage.

Gaining Confidence with Your Used Equipment Purchase

Although there are several advantages to buying used equipment, in a lot of people’s minds there is generally still some risk. After all, you expect the piece of equipment to be durable, dependable and ready to perform it

can become frustrating when it doesn’t meet these expectations.

To help build assurance in your decision to purchase a piece of used equipment, Vermeer launched the Vermeer Confidence Plus Pre-Owned Program in 2015. Similar to a vehicle “Pre-Owned” program, the Vermeer Confidence Plus program offers a service plan that helps protect the productivity and value of your Vermeer baler, helping to manage potential expenses and provide you with peace of mind.

HOW IT WORKS:

In order to be backed by the Vermeer Confidence Plus Pre-Owned Program, balers must undergo a detailed multi-point inspection by a Vermeer technician. Once approved, the customer can purchase a coverage that lasts 12 months and covers hydraulics (cylinders, valves and hydraulic valve), rollers (idler and drive), bearings (drive roller bearing and idler roller bearing), gearboxes, PTO shafts, cross drive shafts, electronic controllers and wiring harnesses (tractor and baler).

QUALIFYING EQUIPMENT:

Vermeer or non-Vermeer balers less than 7 years old and less than 20,000 bales of use. Non-Vermeer used balers fall under the same age and use limitations.

ADVANTAGES:

- Convenience: We know you are on the move so the Vermeer Confidence Plus program plans are honored at all participating Vermeer dealers.

- Dealer-Certified Technicians: Required maintenance and service will be conducted by Vermeer dealer service technicians using genuine Vermeer parts to help keep your baler running when it’s time to make hay.

- Resale Advantages: A well-maintained baler coupled with detailed service records from your Vermeer dealer can offer future owners additional assurance when they make their purchase and may result in higher resale values.

- Transferable: If you sell your Vermeer baler within the coverage term, the Vermeer Confidence Plus program plan is fully transferable to the new owner. Look for the Vermeer Confidence Plus decal when scouting your next used baler or ask your local dealer for more information.